In 1863, John H. Fairbank encountered a dilemma in one of his oil fields. Two wells were located at such a distance that only one steam engine could be placed between the two pumps, the steam engine and its pumping outfit being quite large. Fairbank decided to solve the problem by adding an extra pole to the steam engine, thereby connecting two wells to a single power source and the jerker line system for pumping oil was born.

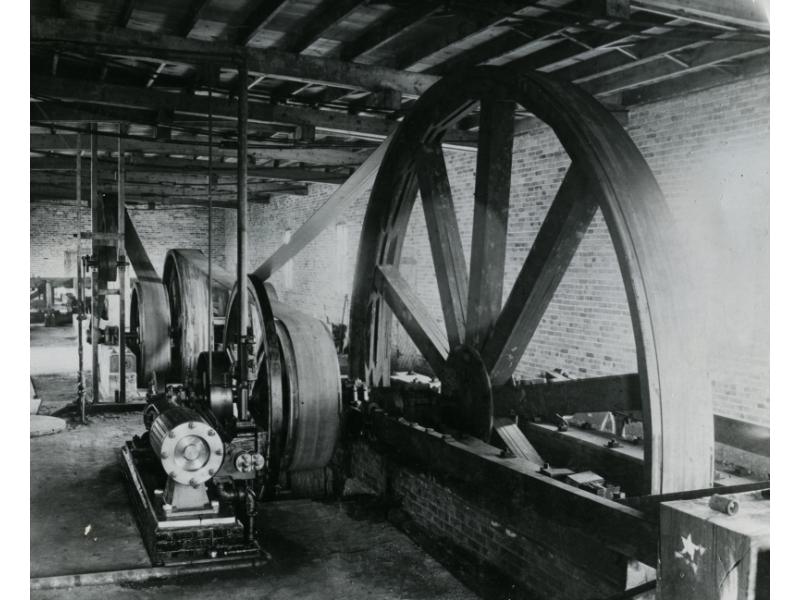

Jerker lines can be seen throughout the oil heritage district of Lambton County and allow 20 wells or more to share a single power source, providing a much needed efficiency especially once most of the wells declined in production. The central power source is called the pumping rig and it operates much like the steam engine of a single-well system, only on a much larger scale. The Fitzgerald rig in Petrolia was built in 1903 and was the largest rig of its type, serving about 500 wells. Eight pumping rigs are still in operation, one of which is on the Fairbank oil field. A steam engine was used to drive a vertical wheel which turns a central shaft. This central shaft, through a series of gears, powers four eccentric cranks connected to pitman arms which provide the back and forth motion to the slide blocks. From here, jerker lines attached to the slide blocks disperse the power to the pump blocks.

The jerker lines themselves are made of 30-foot ash or fir poles connected together lengthwise and suspended from wooden posts using rod hangers which allow the poles to swing back and forth. More modern jerker lines also use cable or metal rods instead of wooden poles. The jerker lines are then connected to the pump blocks and pull on the walking beam, lifting the pump.

Not all wells are placed in a direct line from each other and field wheels allow the direction of the jerker lines to be changed. Field wheels also divide the jerker line into multiple directions, so that a single line connected the field wheel will provide power for the multiple lines attached to this central location.

Rod hangers are used to hold up the ash poles of the jerker line, allowing the poles to swing back and forth.

Rod hangers are used to hold up the ash poles of the jerker line, allowing the poles to swing back and forth.  A field-wheel is used to transfer power from a central source to multiple lines in different directions.

A field-wheel is used to transfer power from a central source to multiple lines in different directions.  Fitzgerald Pumping Rig in Petrolia

Fitzgerald Pumping Rig in Petrolia  A vertical eccentric field-wheel with steel-rod lines, a type of technology used in Pennsylvania.

A vertical eccentric field-wheel with steel-rod lines, a type of technology used in Pennsylvania.  A double jerker line powered by a central rig disappears into the distance, providing power to far-off oil wells.

A double jerker line powered by a central rig disappears into the distance, providing power to far-off oil wells.  A pair of slide blocks are powered by the central rig (inside) and provide the back-and-forth motion to the jerker lines.

A pair of slide blocks are powered by the central rig (inside) and provide the back-and-forth motion to the jerker lines.  A field-wheel is used here to change the direction of the jerker line.

A field-wheel is used here to change the direction of the jerker line.

Add new comment