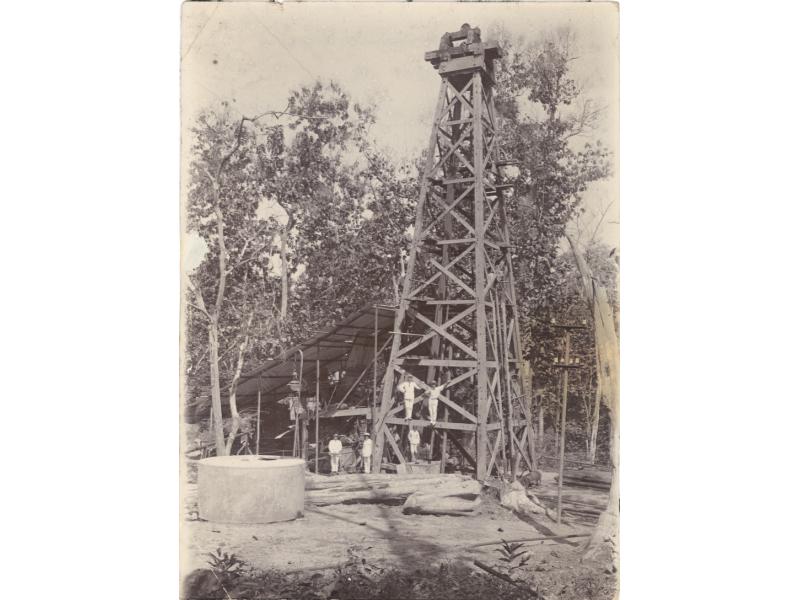

When oil was first discovered in Lambton County, the drillers collected the oil in barrels as it was being produced and sold the barrels to the refineries for processing. By the late 1860s, however, the number of wells was growing rapidly and the refineries were operating at capacity so that it became necessary to store the oil until it could be used. Oil was being collected in every available wooden tank and barrel until the fields around the oil wells were filled with storage vessels.

One Saturday night in 1867, a fire broke out in one of the full oil tanks in Petrolia. Although the men rushed out to the field to try to drain the tank, they were too late and the wooden tank collapsed, sending burning oil towards the rest of the tanks. Soon each of the tanks caught fire and for two weeks, the fields continued to burn over an area of 12 acres.

After this disaster, John D. Noble devised a system for storing the oil that would prevent such a disaster from reoccurring. The clay soil which makes up much of the area is very thick and provides the perfect material for storing oil. Noble therefore came up with the idea of building underground storage tanks, eventually forming the Petrolia Crude Oil Tanking Company. The clay was dug to a depth of 60 feet and 30 feet in diameter, which provided a capacity of about 8,000 barrels of oil. Once the excavators reached a depth of about 20 feet, they built a wooden sheathing around the inside of the tank and left the bottom un-planked. The wooden sheathing consisted of lumber cut into the segment of a circle, forming rings up the side of the tank. This served only to keep the clay from caving in. The clay itself held the oil tightly, without leaks and kept it at a constant temperature while a wooden cover prevented lightning from striking the oil. These natural clay properties made in-ground wooden storage tanks a particular feature of the oil fields of Lambton County.

Later, Petrolia's Oil Well Supply Company began to ship wooden storage tanks with vertical staves in pieces so that they could be assembled on site. These tanks were put together above ground. Once assembled, the excavated clay hole was filled with water and the tank placed into the hole so that it floated on top of the water. Then, the water was slowly pumped out of the hole until the tank rested at the bottom.

After the initial gush of oil, water started to enter the wells and it became necessary to build separating tanks. These were constructed similarly to the storage tanks, though on a smaller scale. The oil and water mixture entered the separating tank from the well pump and as it settled, oil floated to the top. The water at the bottom was siphoned off and the oil flowed through a pipe into the storage tank.

By the late 1870s, wrought-iron and, later, steel storage tanks began to make an appearance, although the threat of lightning strike was sometimes a concern with these.

After a field of wooden storage tanks, like this one, caught fire, John D. Nobel decided to build in-ground storage tanks.

After a field of wooden storage tanks, like this one, caught fire, John D. Nobel decided to build in-ground storage tanks.  A man stands on top of an above-ground wooden storage tank.

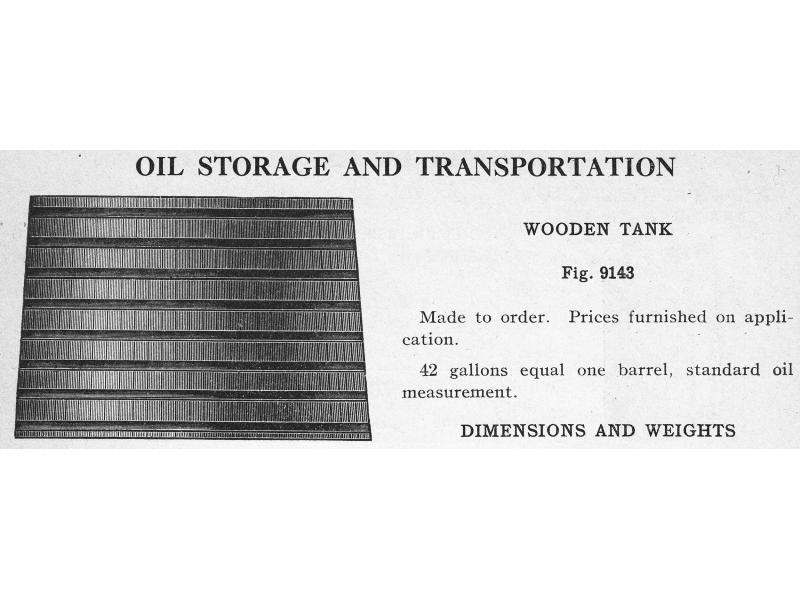

A man stands on top of an above-ground wooden storage tank.  Wooden storage tanks could be ordered from the Oil Well Supply Company which shipped the containers in pieces to be assembled on site.

Source: Oil Well Supply Company General Catalogue No. 29, 1911.

Wooden storage tanks could be ordered from the Oil Well Supply Company which shipped the containers in pieces to be assembled on site.

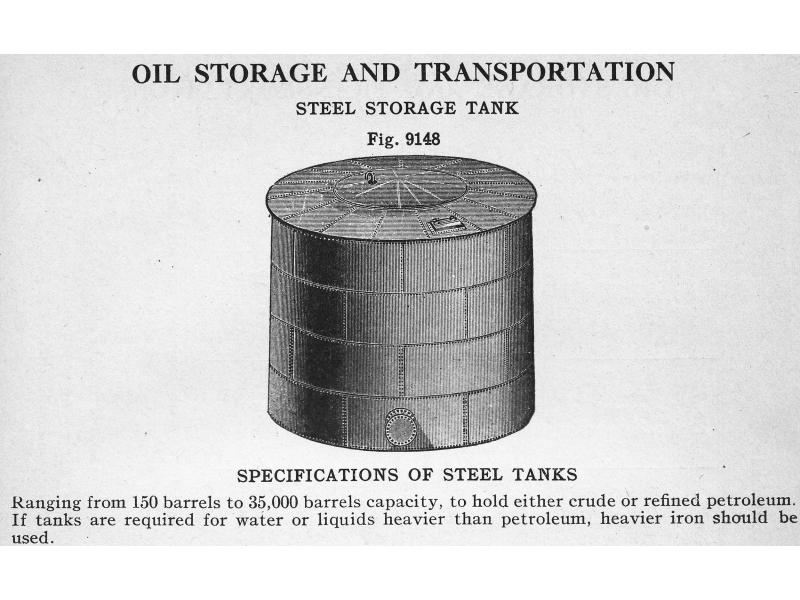

Source: Oil Well Supply Company General Catalogue No. 29, 1911.  Later, steel storage tanks were also made available.

Source: Oil Well Supply Company General Catalogue No. 29, 1911.

Later, steel storage tanks were also made available.

Source: Oil Well Supply Company General Catalogue No. 29, 1911.  In the oil fields of Java where the soil conditions were not the same hard clay as Lambton County, above-ground steel storage tanks were used.

In the oil fields of Java where the soil conditions were not the same hard clay as Lambton County, above-ground steel storage tanks were used.  "Hot-tubs", or separating tanks, collect the oil directly from the wells and separate the water from the oil.

"Hot-tubs", or separating tanks, collect the oil directly from the wells and separate the water from the oil.  Pipelines coming from the oil wells pour the mixture of oil and water into the separating tank.

Pipelines coming from the oil wells pour the mixture of oil and water into the separating tank.  This in-ground wooden storage is over 100 years old and still collects oil from the separating tank next to it. A pipe runs out to the road where oil trucks will make their collection and deliver the oil to the refinery.

This in-ground wooden storage is over 100 years old and still collects oil from the separating tank next to it. A pipe runs out to the road where oil trucks will make their collection and deliver the oil to the refinery.

Add new comment